FORMULA FIELD ON ROUTE DETAILS IN D365

- 12 Kasım 2023

On this post, I am going to go over the “Formula” field within route functionality.

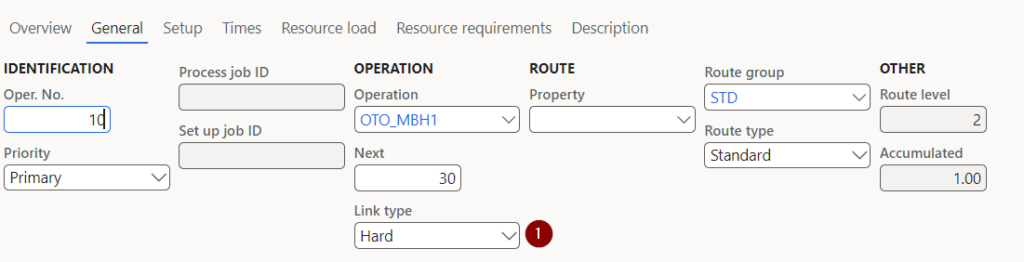

Note: Master plan demonstration shown below is going to be originated from 400 meters of sales order quantity. Coverage group is “Requirement”. Sundays are closed for pick-up on the calenders assigned to machines. Resources have finite capacity and %100 efficiency. Operation number 20 should be checked.

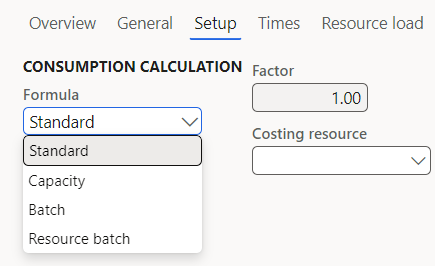

There are 4 options on formula field:

Note: The only purpose of these field values is to calculate the run time of the regarding operations. System does not utilize the capacity of resource based on “Formula” values.

1- Standard: This is the default and mostly-used value. System calculates regarding operation’s process time as [(Run time) * (Hours/Time) * (Order Quantity)] / (Process quantity). For the example above: Process time = [(2,05) * (1) * (400)] / 1= 820 hours. Total time for the operation = 820 + 7 + 1 = 828 hours.

2- Capacity: System calculates regarding operation’s process time as [(Produced quantity / Resource capacity)] / Factor. System ignores Run time, Process quantity and Hours/Time on routes. For the example above: Process time = [400 / 40]= 10 hours. Total time for the operation = 10 + 7 + 1 = 18 hours.

Note: Capacity unit on Resources form is only informative field. System does not use this value to convert to any unit of measure.

3- Batch: I know most of you wonder how it works :-). For “Batch” value, i prepared new example. Sales order quantity is 121 meters for the item (Inventory unit is also meters). Process time is calculated based on “Process quantity” under “Times” tab of Route details. System rounds the produced quantity up to multiply of process quantity. If production quantity is 61 meters, system rounds base quantity up to 2*60 = 120 meters and calculates process time as if the production quantity is 120 meters (batch quantity).

My sales order quantity is 121 meters and lets check the result:

System rounded production quantity (121 meters) up to 180 meters. Process time of production is: [(Run time) * (Hours/Time) * (Batch quantity) / (Process quantity) = (3 * 1 * 180) / 60 = 9 hours. Total time required for production is : 9 + 1 + 7 = 17 hours.

4- Resource batch: System calculates process time as [Order quantity / (Resource batch capacity / Factor)] * Run time. System ignores Process quantity on route. For the example above: Process time = [400 / (40/1) ] * 2.05= 20.5 hours. Total time for the operation = 20.5 + 7 + 1 = 28.5 hours.

Kind regards,

Hi, Mehmet!

Thanks for explaining this!

Notice how Resource batch behavior resembles Batch formula, meaning it is non-linear in proportion to order quantity (scheduled process time is a multiple of Run time value).